«Sand blasting» — a technology for material processing, in this case, glass, vozdushnopeschannoy jet of high pressure. The result of processing of glass sand plant, is a matte glass surface.

Sandblasting business is gaining more and more speed. Every endeavor to decorate your home with beautiful furnishings. The mirror coated with a beautiful picture or a photograph will give your home personality.

You can open your business with minimal investment in artistic processing mirrors.

Содержание

Everything you need

— To buy (you can do yourself) sander

— Prepare a template and the mirror image

— Produce templates, which will bear the image

— Buy ready-made mirrors, or to order the right size for your template

— Apply the stencil to the Mirror

— Apply a matte image on the glass surface of mirrors, using a sand blasting technique.

Now consider everything in order ….

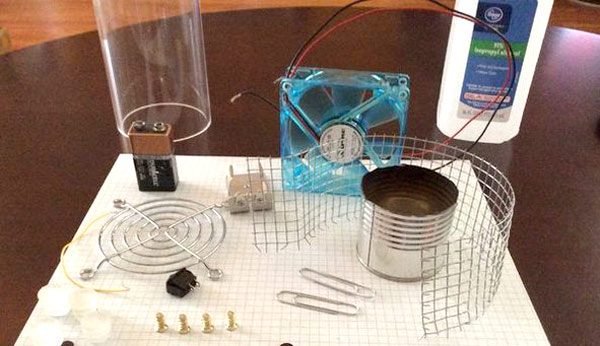

Step One. Acquisition sandblaster

Acquisition peskostrunogo apparatus is the main issue, or not even worth doing it. You certainly could do it yourself (nothing complicated about the design is not), but it’s better to get ready (default) sander.

Grit chamber — a place to work. You can install at home (unlikely) or in the garage. Do not forget to buy and a fraction (the same sand) for your vehicle! At the initial stage (try and) you can do without it.

Possible to produce a similar box (as shown, as a material — particleboard).

Attention! When you work requires the use of personal protective equipment: overalls, dust mask, goggles and gloves.

Step Two. Making a template image.

For the preparation of the stencil (single use) need a template image, which can be obtained:

— Establish himself in a computer program CorelDRAW

— Get ready (available on CD or DVD with a vector image)

— To order in any advertising agency or a private master (this method is good that you fit the image at the mirror, glass, etc.)

We make a stencil.

Stencil is made of PVC film, preferably white (as thick and cheap), used in outdoor advertising (self-adhesive tape, sold, for example, an advertising agency). The thickness of the stencil will depend on the quality of work, as if too thin jet of sand and air can penetrate the stencil and spoil the product.

Cut on the plotter itself stencil.

Step Three. Prepare workpiece (mirror glass)

We buy in a store or order the size and shape of the workshops, carved on order (round, square, polygonal, etc.).

Check processing (grinding) edge.

The question of fixing the mirror on the wall to solve individually (drilling, double-sided adhesive tape strip or hangers on the back side of the liquid nails).

Step Four. Impose a stencil

At the initial stage can be trusted with it advertisers, bringing them their piece of glass or mirrors, vnimatlno learn the technology of film deposition on glass. In the future, better to do it myself, so as not to increase the final cost of your services / product

To do this you will need:

— Transport tape (transparent film cut to move from a self-adhesive film on the surface of the figures)

— Squeegee — plastic rectangular instrument similar to a paint spatula (for priglazhivaniya adhesive film).

We transfer the stencil on the freighter (pre-clearing of unnecessary detail picture that turned out after the cutting plotter). Remove from the stencil paper substrate and packs the resulting image on the mirror or glass.

Remove the transport worker (as the stronger adhesive PVC transporter, the latter is removed, leaving a stencil on the glass or mirror).

Check for air bubbles, otherwise puncture and smooth.

Leave for a day (stencil hardens).

Step Five. Draw an image sandblasted

The mirror is placed vertically with a slight slope back to stability (on the stand, which resembles an easel (stand under the painting) artists).

With sandblaster do matte image, leading to a state of uniform white.

Do not hold nozzle of the gun closer to 20-30 cm, to try to maintain an equal distance in the processing (different distances — the deepening of various processing), to check periodically on the bare patches (at different angles to look at an object processing).

Remove foil, clean with solvent adhesive residue stencil.